Work sampling is a statistically based technique utilized for analysing work performance and machine utilization by direct observation, but without a stop watch. So work sampling is another useful technique of work study.

This technique is particularly useful to estimate the proportion of delays or idleness’s occurring in a enterprise/plant and attributing the cause for it, such as power failures/input delays, machine cleaning, machine breakdowns and manpower idling or in other words, estimating proportion of time spent by an executive in attending meetings, telephoning or reading etc.

The stop watch technique for time estimation is extremely time consuming and therefore not feasible.

Work sampling is a technique for establishing standard times of activities. This method also known as activity sampling was devised by L.H.C. Tippet in 1934. This technique is more suitable for analysing group activities and repetitive activities which take longer duration.

If a given individual performs more than one activity, then the time standard for each activity can be computed with the help of this method. For example, on a printing press, a single operator/worker will be doing composing, proofreading, printing etc. The time standards for all these activities can be determined with the help of work sampling method.

The method of work sampling consists of taking a large number of instantaneous observations randomly, rather than taking observations continuously as is done in various production investigations/ studies. This method is a sampling technique and depends upon laws of probability.

A sample taken at random from a large population provides a good estimate of the distribution of the population because it tends to have the same distribution as the population.

Some examples are as follows:

(1) A decision regarding the cooking of rice is taken by having a sample of rice from a boiling/ cooking pot and pressed between fingers.

(2) A decision regarding the quality of wheat bag to be purchased is made by examining a sample of wheat from a bag.

Hence, work sampling is a technique of determining the percentage occurrences of a certain activity (a group of processes, machines, or workers) with the help of statistical sampling and random observations. When the sample size is large enough and random observations are made indeed, there is quite a high probability that the observations would reflect the real situation plus minus a certain margin of error.

“Work sampling is a method in which a large number of instantaneous observations are made at random time intervals over a period of time or a group of machines, workers or processes/operations. Each observation records what is happening at that instant and the percentage of observations recorded for a particular activity or delay/idleness is a measure of the percentage of time during which that activity or delay/idleness occurs”.

Work sampling has a long and impressive list of applications but all of them fall, into one of the following three categories:

(i) Work sampling can be used as ratio study of working and idle times.

(ii) It can be utilized as performance sampling study in which working and idleness on working times are measured and, a performance index is prepared.

(iii) If can be used as a work measurement technique.

It states that the percentage of observations recorded on an operation/process in any state is a reliable estimate of the percentage time the operation/process is in that state, provided, “sufficient number of observations is taken at random”.

It may be noted that here, particular stress should be paid on the words “random” and “sufficient number of observations”. In this technique, some error may occur but the magnitude of error tends to decrease as the number of samples increases.

Work sampling is a sampling method and depends upon the laws of probability. A sample taken at random from a large population provides a good estimate of the distribution of the population. To make it more clear, let us consider the following example.

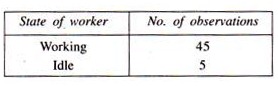

A worker while working during his shift either does the job assigned to him or remain idle for one or the other reason. The following table shows that out of total 50 observations, there were 45 working observations and five idle observations.

This table indicates the working time and idle time.

In this example, the idle time percentage would be -5/50x 100 =10%

Working time would be x 100 = 90%

This investigation is for one worker for a shift of 8 hours a day and indicates that the operator was idle for 10% or 48 minutes in a shift of 8 hours (480 minutes) while working for 90% or 432 minutes in one shift.

The result obtained by work sampling technique differs considerably from the results actually achieved by continuous recording of time. The accuracy of result depends upon the number or observations and the limits of confidence level because the sampling procedure used involves certain degree of error. So it is important to decide, what level of confidence is desired in the final “Work Sampling” results.

During a investigation, if we increase the number of observations considerably and in each observation then number of activities are large we can obtain a smoother curve called normal distribution curve as shown in Fig. 18.12.

The most common confidence level is 95%. The area under the curve at 2 sigma or two standard deviations is 95.45% which is rounded off gives 95%.

This indicates that the probability is 95% of the time the random, observations will be true or represents the fact and 5% of the time false or will not. For majority of cases, an accuracy of 5% is considered satisfactory. This is usually referred to as the percentage standard error.

Sample Size Determination. To obtain a desired accuracy level an analyst is required to take sufficient number of observations.

Following formula may be used for finding the requisite number of observation in order to achieve the desired accuracy:

Limit of error = Sp = x √p(1-p)/N

Where x = 1. 2 or 3 for confidence level of 68%, 95% and 99% or one sigma, two sigma three sigma confidence levels respectively.

S = Desired relative accuracy.

P = Percentage occurrence of an activity or delay expressed in decimal e.g., 10% = 0.10

N = Sample size or total number of random observations.

Assume a Confidence level of 95% and desired relative accuracy of ±5%. Determine the number of observation required for the study. The work sampling method is to be used to determine the utilization of a group of drilling machines. The Preliminary study indicates that the machines are utilized for about 60% of the time.

Example 2:

A work sampling investigation was conducted to estimate the time for which the workers in plant remain idle.

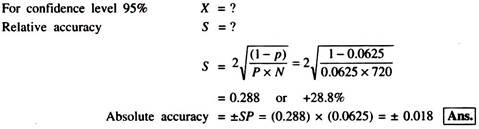

A total of 720 observations were made about the workers. In 45 observations the workers were found idle. If the confidence level is 95% Determine the absolute accuracy of the current estimate of the proportion of time consumed by idleness.

Solution:

Total no. of observations N =120

P = Proportion of idle time = 45/720 = 0.0625

The procedure to be adopted for conducting a work sampling investigation will depend upon the type of application. As much as possible different methods will be applied for taking observations. An analysis of the data shall be conducted to suit the case.

But the following general procedure is applicable in each study:

(1) Define the Problem:

State the main objectives or purpose of the study clearly. This invariably includes the detailed description of each element of the work. The analyst must explicitly know what are the different states of the operator’s activity which are to be observed. Sometimes it will be required to observe the operator as either working or idle.

(2) Design a chart for recording information’s.

(3) Make a pilot study i.e………… preliminary observation.

(4) From the preliminary observations, compute the delay percentage p.

(5) Determine the accuracy and confidence level desired for the investigation.

(6) Obtain the approval of the foreman of the department or section head concerned in which study is to be made. Obtain the cooperation of the workers/operators to be studied and they should also understand the aim/purpose of study.

(7) Calculate the number of observations required for a chosen level of confidence and accuracy. Because work sampling is a statistical sampling procedure and the estimate obtained would become more and more realistic as the sample size increases.

Thus, more number of observations will make the study more accurate. With this increase in number of observations, the cost and time of study would increase. Thus the number of observations to be taken are decided in the light of precision and confidence required.

(8) Determine the number of observers needed. Select and instruct these people.

(9) Determine the number of days/shifts required for the study.

(10) Plan the schedule of observations such as time for taking and the route to be followed by the observer.

(11)Proceed with sampling of observations in the chart (record sheet) making notes of any unusual points.

(12) Analysing the data and presenting the results. The work sampling data are analysed during the study in order to check if the things are going according to plan or not. The data is usually summarized at the end of each day.

This provides the trend for the next day’s work and gives information regarding precision obtained in the study so far and how much more is required. At the end of study, the final analysis are performed and required results are presented. These would provide either ratio delay, performance study-or-work measurement.

Work sampling is a highly useful method to solve variety of problems in various types of activities involving groups of machines, processes or people. With the expansion and growth of industrial plants/ enterprises it has become increasingly difficult for executives/managers to collect information and facts about what goes on in their manufacturing sections.

Work sampling is useful and can be applied when:

(1) Work of teams has to be investigated/studied.

(2) There is clear distinction between working time and idle time.

(3) To indicate areas of delay.

(4) To investigate and to locate areas underutilization.

(5) For establishing overall performance levels.

(6) For determination of machine utilizations.

(7) In determining the distribution of duties among a group of workers.

(8) In the study of nature, causes and extent of interference with effective accomplishment of a project.

(9) For the purpose of cost control and accounting.

(10) To estimate allowances for unavoidable delay.

(11) In ware housing and shipping operations to pin-point delays so that changes in the layout or method could be identified which reduces delays.

(12) It is preferred when the cost of using other work measurement techniques for timing a job appears to be more.

(1) It is a cheaper technique than time study and production study.

(2) Only one analyst can perform work sampling study of many activities.

(3) Observers does not require much training.

(4) It is more useful in non-repetitive and indirect jobs.

(5) Many operations or activities which are impractical or costly to measure by time study can readily be measured by work sampling.

(6) Observations may be made over a period of days or weeks thus decreasing the change of day to day or week to week variations.

(7) Observations are made at random intervals depicting the usual routine of the worker as against continuous observations of a worker for a long time in time study which may not reveal his usual routine (being conscious of being observed).

(8) The work sampling may be interrupted at any time without affecting these results.

(9) The study can be made with pre assigned degree of reliability.

(10) The study is less tiring and less tedious.

(11) It is less time consuming.

(12) As the study is spread over a number days, it is likely to be more representative and is less affected by day to day variations.

(1) Compared to time study, the statistical approach of work sampling study is difficult to be understood by worker.

(2) The operators may not understand value of sample size and accuracy etc.

(3) It is not economical for the study of jobs of short duration or operators and machines, spread or located over wide area.

(4) The worker may change his work patterns on the sight of work sampling observer and try to look more productive, resulting incorrect information which are meaningless.